Laser & Water Jet Cutting

Laser & Water Jet Cutting

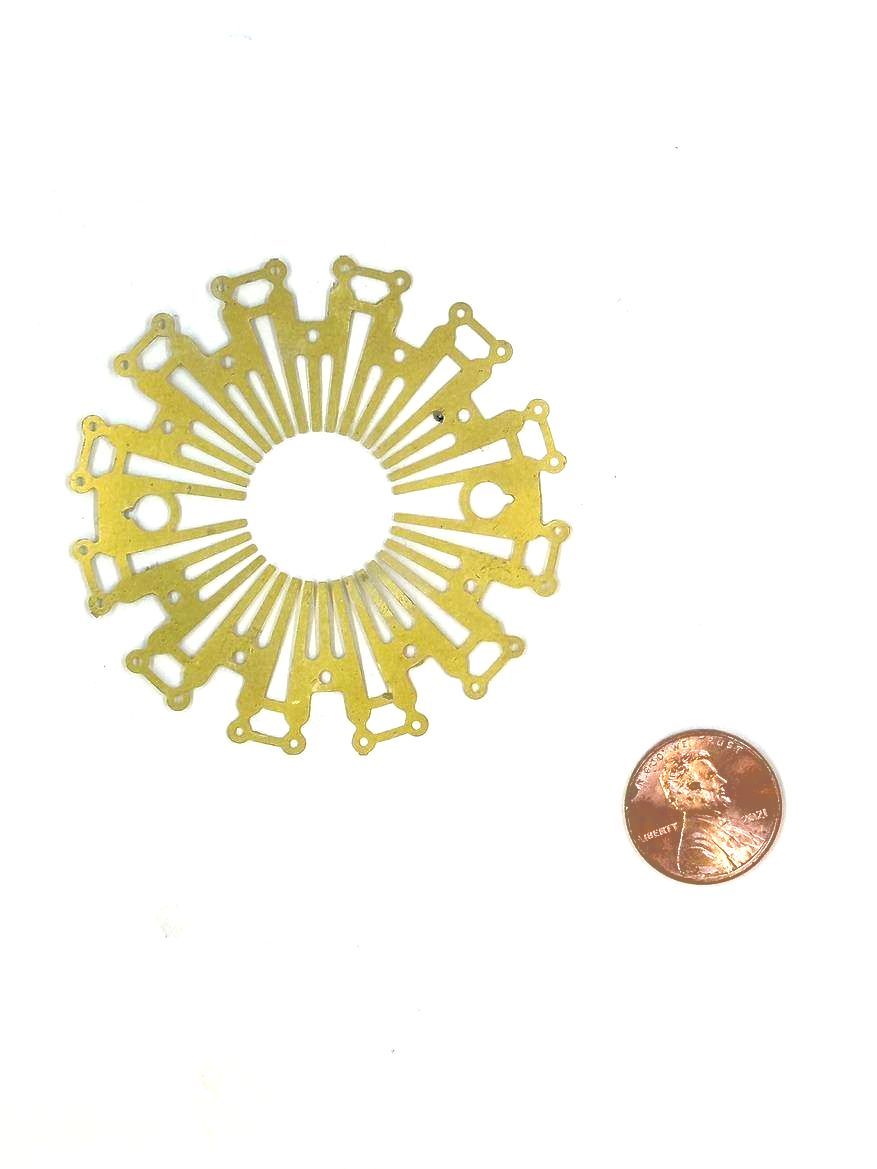

Our Laser and Water Jet Cutting Services provide high-precision, non-contact cutting solutions for a wide range of materials, ensuring superior accuracy and minimal material distortion. These advanced cutting technologies allow us to produce intricate, complex geometries with tight tolerances, making them ideal for aerospace, medical, automotive, electronics, and industrial applications.

Laser Cutting is highly effective for metals, plastics, and composites, offering exceptional edge quality and intricate detailing. Using fiber and CO₂ laser systems, we achieve tolerances as tight as ±0.002 inches, allowing for the production of fine, high-precision components with minimal heat-affected zones (HAZ). This method is particularly advantageous for thin-gauge sheet metal, precision electronic components, and intricate designs requiring high repeatability.

Water Jet Cutting, on the other hand, is a cold-cutting process that can handle thicker materials without introducing thermal distortion. It is suitable for metals, ceramics, glass, stone, composites, and rubber, offering precision tolerances of ±0.005 inches. Water jet cutting is particularly valuable for heat-sensitive materials and applications requiring smooth, burr-free edges without secondary finishing.

With our state-of-the-art cutting technology, we ensure high-speed production, cost-effective material utilization, and superior quality control to meet the most demanding specifications. Whether it's prototype development or high-volume production, our Laser and Water Jet Cutting Services provide the precision and reliability needed for today’s most complex manufacturing challenges.

Precision & Versatile

At APL Manufacturing, our Laser & Water Jet Cutting Services provide high-precision, versatile cutting solutions for a wide range of materials and industries. Using advanced laser technology, we achieve clean, intricate cuts with exceptional accuracy, making it ideal for thin-gauge metals, plastics, and composites. Our water jet cutting capabilities complement this by offering a cold-cutting process, eliminating heat-affected zones (HAZ) and ensuring material integrity for thicker or heat-sensitive materials like stainless steel, titanium, and ceramics.

These cutting-edge processes cater to industries that require precision, speed, and efficiency, including aerospace, automotive, medical, and industrial manufacturing. Customers benefit from tight tolerances, reduced material waste, and no mechanical stress on the final product. Whether you need prototyping or high-volume production, our combination of laser and water jet cutting ensures that we can handle diverse material requirements while maintaining the highest quality standards. Choose APL Manufacturing for cost-effective, precision-cutting solutions that enhance your product performance and manufacturing efficiency.

Request a Quote

Contact Us

We will get back to you as soon as possible.

Please try again later.

Our Address

Email: quotes@prototype-shortrun.com

Tel: (714) 449-9661

1310 W. Collins Ave.

Orange, CA 92867

Find Us

APL Manufacturing Inc.