Brazing

Brazing

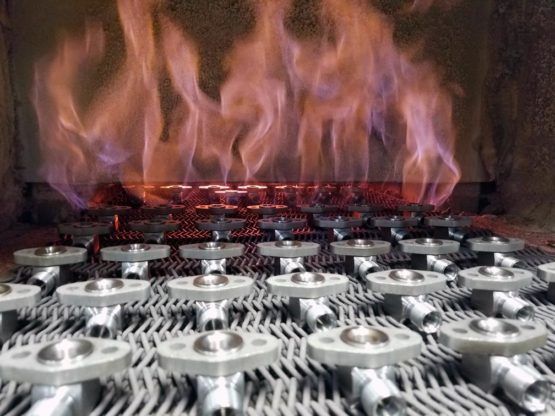

Our brazing services provide a high-strength, permanent joining solution for complex assemblies, offering superior performance for mission-critical applications across aerospace, automotive, medical, and industrial sectors. Brazing is a metallurgical bonding process that utilizes a filler metal with a lower melting point than the base materials, allowing for a strong, leak-proof joint without compromising the mechanical properties of the components. This process ensures uniform heat distribution, minimal thermal distortion, and the ability to join dissimilar metals, including stainless steel, aluminum, copper, titanium, and nickel-based alloys.

We specialize in tight-tolerance, high-precision brazing for thin-walled components, complex geometries, and multi-part assemblies, achieving tolerances as precise as ±0.001 inches. Our expertise covers vacuum brazing, atmosphere brazing, induction brazing, and furnace brazing, allowing us to meet specific strength, corrosion resistance, and thermal performance requirements. With extensive quality control and metallurgical expertise, we ensure consistent, defect-free joints that exceed industry standards. Whether for high-temperature applications, fluid handling systems, or structural components, our brazing solutions provide exceptional strength, durability, and precision to meet the most demanding engineering challenges.

High-Strength, Precision Joining

Brazing is a highly reliable and precise metal-joining process that creates strong, leak-tight joints without melting the base metals. Using a filler metal with a lower melting point, brazing allows for the permanent bonding of dissimilar metals, intricate assemblies, and components that require exceptional strength, thermal resistance, and corrosion protection. This process is widely used in industries such as aerospace, automotive, medical devices, and industrial equipment, where precision and durability are critical.

At APL Manufacturing, we specialize in controlled atmosphere and vacuum brazing, ensuring uniform heating, oxidation prevention, and superior joint integrity. Our expertise allows us to manufacture complex, high-performance assemblies while maintaining the original properties of the base materials. Whether you need heat exchangers, fuel system components, medical instruments, or electronic enclosures, our brazing solutions offer cost-effective, high-strength bonding that outperforms traditional welding or mechanical fastening. By choosing APL Manufacturing, you gain access to cutting-edge brazing technology, expert craftsmanship, and a commitment to quality that ensures your components meet the most demanding industry standards.

Request a Quote

Contact Us

We will get back to you as soon as possible.

Please try again later.

Our Address

Email: quotes@prototype-shortrun.com

Tel: (714) 449-9661

1310 W. Collins Ave.

Orange, CA 92867

Find Us

APL Manufacturing Inc.