APL Manufacturing

11 Companies

Managed by APL

4 States

CA, MA, MI, & PA

500+ Employees

Spread across the U.S.

24/7

Production capabilities

Meet APL

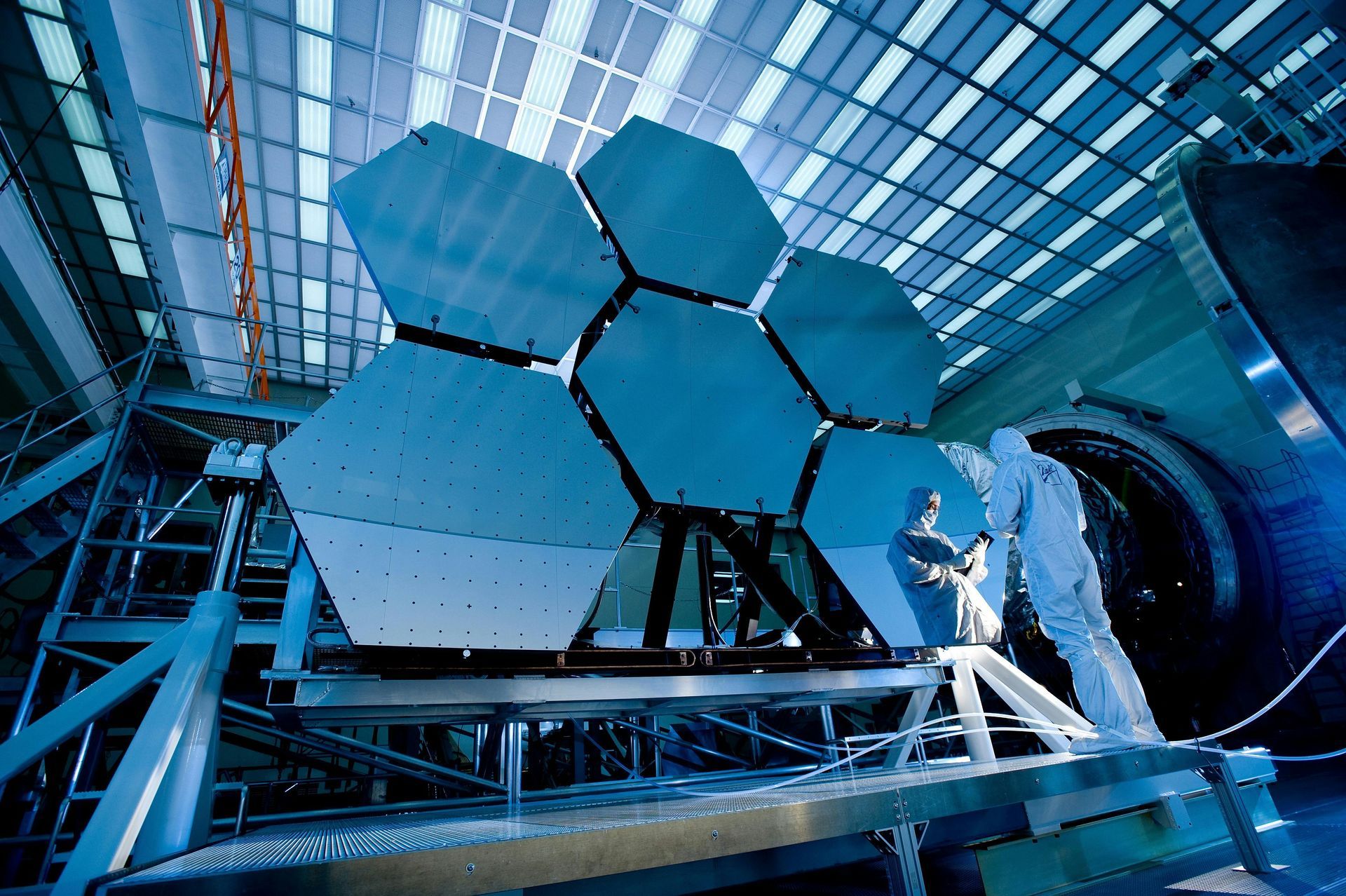

With eleven subsidiary companies strategically located across the United States, we are uniquely positioned to support industries such as aerospace, automotive, defense, energy, medical, recreation, technology, and transportation. Our diverse portfolio includes industry leaders like American Etching & Manufacturing and Plateronics, allowing us to offer comprehensive surface modification solutions, including electroplating and photochemical machining. Additionally, our advanced surface treatment capabilities, such as brazing and metal heat treatment, ensure superior performance and durability for mission-critical applications.

At APL Manufacturing, we combine innovation, precision, and collaboration to deliver exceptional results for our partners. Whether you need high-volume production, specialized manufacturing services, or integrated supply chain solutions, we have the expertise, technology, and nationwide reach to support your evolving manufacturing needs.

Who We Are

APL Manufacturing is a

premier, vertically integrated network of customer-focused manufacturing companies, delivering

precision-engineered solutions across a wide range of industries. Our expertise spans

thick and thin gauge stamping, EDM, plastic injection molding, surface modification, brazing, and metal heat treatment, enabling us to provide

high-quality, cost-effective manufacturing services tailored to our customers' needs.

Our Companies

Supplier of precision, high-reliable, thin gauge metal subcomponents

Creating precision prototype parts utilizing SCHMIDT Technology presses

Providing precision machined parts, including drill bushings and tooling components

Provides quality chemical processing and surface coatings for aerospace and automotive industry

Our Services Include:

Photochemical Machining

Industries We Serve

Aerospace

Automotive

Defense

Energy

Medical

Recreation

Technology

Transportation

Aerospace

Automotive

Who We Are

At APL Manufacturing, we are committed to delivering value, reliability, and excellence in every project. Explore our capabilities and see how we can support your manufacturing needs.

APL Manufacturing is a vertically integrated contract manufacturing group delivering precision-engineered solutions across a wide range of industries. With expertise in metal stamping, EDM, plastic injection molding, surface modification, brazing, and heat treatment, we provide comprehensive manufacturing capabilities that support high-performance applications.

By combining advanced manufacturing processes with cutting-edge surface treatments and material enhancements, we help our customers achieve higher quality, improved durability, and greater efficiency in their products. Our focus on precision, scalability, and innovation ensures that we can meet the evolving needs of modern industries, from small-batch production to high-volume manufacturing.